Briquetting Plant

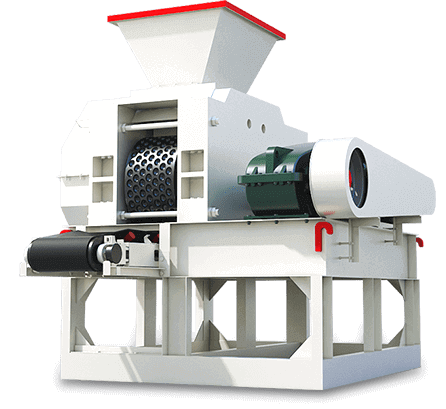

Briquette plant is used to presses powdery materials into balls with different shapes. The final product is easy to transport, to burn and to smelt.

Production Capacity

1-100t/hInput Size

PowderFinal Size

>2cm

Welcome to visit our actory in China. If not convenient, factory visit online available.

Briquette plant is used to presses powdery materials into balls with different shapes. The final product is easy to transport, to burn and to smelt.

Production Capacity

1-100t/hInput Size

PowderFinal Size

>2cm

Under the role of reducer, it transmits power to two pressure rollers at the same time , and makes the two pressure rollers rotate towards each other. During the rotation of the two pressure rollers, the material naturally enters the ball mold on the pressure roller. When the rollers rotates, the pressure on the material is slightly larger and larger. When the material rotates to the contact point of the two rollers, the pressure on the material has reached its peak value. Under the action of huge linear pressure, the material turns from powder into finished balls, thus completing the whole process.

The optimization of the main transmission structure not only facilitates manufacturing, installation, adjustment and maintenance, but also reduces the weight of the equipment while fully ensuring the quality.

Transmission device input adopts hard tooth surface synchronization box. It can not only meet the operating conditions of the equipment, but also facilitate the accurate adjustment, better extrusion effect, the final product with high density.

It can be used to process kinds of powdery materials, low cost, easy operation and maintenance.

1-3t/h, 3-5t/h, 5-8t/h, etc, usually for small production scale, with low costs.

10-20t/h, 30-50t/h, 50-100t/h, etc, usually for medium and large production scale.

All of briquette machines are factory-direct sold at 100% factory price, saving costs.

We have full models briquette machine in stock, fast delivery and shipping.

Price range is about 2,000-40,000 dollars. Click for specific price.

Get quotes| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

Our products have been exported to over 90 countries, such as Philippine, Pakistan, Vietnam, Papua New Guinea, Feiji, Tanzania, Ghana, Cameroon, Kenya, South Africa, Nigeria, Somalia, etc.

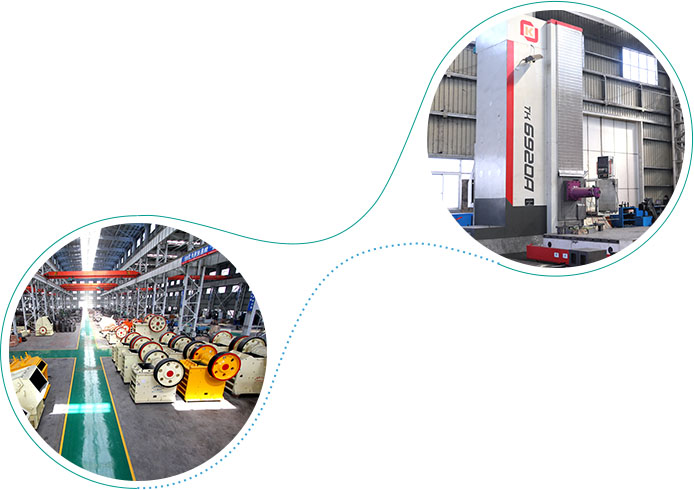

As leading manufacturer and supplier in China, we have three large sized modern workshops, more than 260000 square meters, reliable and trustworthy. We are dedicated to be responsible for every procedure, every product and every customer.

We provide full and professional service system, including customized solution, fast delivery, spare parts, product warranty, product installation, etc.

with over 200 kinds of small, medium and large heavy processing equipment, such as vertical lathe,edge planer, large boring machine, bending roll, etc.

Please fill in the following form, we will send you product details, price and other details as soon as possible.