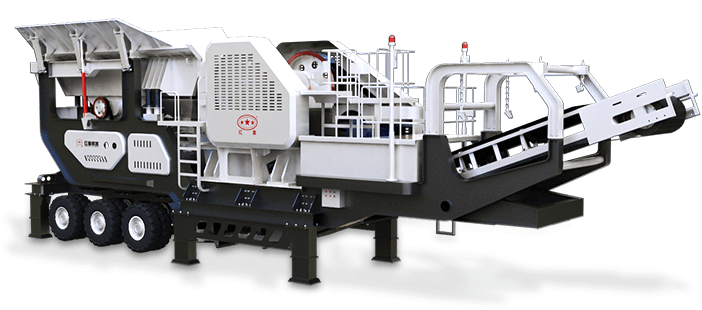

Mobile Crushing and Screening Plant

Mobile crushing screening plant mainly adopts an integrated operation method, which can be operated separately, eliminating complicated assembly and reducing labor consumption. It ensures the safety of equipment production and reliable performance.

Production Capacity

30-900t/hInput Size

≤750mmOutput Size

≤60mm

Processing Materials of Mobile Crushing Screening Plant

It is widely used for primary secondary fine crushing of granite, river stone, quarry stone, rock, boulder, concrete, gravel, aggregate, basalt, limestone, gold ore, iron ore, chrome ore, etc. Adjustable final size meeting different needs. Following is common final output size.

Working Principle of Mobile Crushing Screening Plant

The materials are uniformly transported into the crusher by the feeder. After the initial crushing by the jaw crusher, the closed circuit system is formed through the circular vibrating screen to realize the circular crushing of the materials. The materials after primary crushing will be conveyed out by belt conveyor, thus forming continuous crushing operation.

Advantages of Mobile Crushing Screening Plant

Unit integration

It can be directly operated, eliminating tedious infrastructure installation and labor time consumption

Hydraulic control system

The feeding guard is hydraulically raised and lowered, which is convenient for loading and unloading, convenient for fixing, stable and reliable.

Intelligent operation

One person can operate, the work is more stable, the overall output is increased, and the finished product has complete specifications and good particle shape.

Dual power drive

Switch freely between electtic power and diesel, keeping in good condition anytime and anywhere.

Hot Issues of Mobile Crushing Screening Plant

Hot Sale Types of Mobile Crushing Screening Plant

Mobile jaw crusher, usually equipped with vibrating feeder, for primary crushing.

Mobile impact crusher, mobile cone crusher, usually with vibrating screen, for secondary fine crushing.

Hot Sale Capacity of Mobile Crushing screening plant

30-50t/h, 60-80t/h, etc, usually for small production scale, with low costs.

100-130t/h, 150-200t/h, 250-300t/h, etc, usually for medium and large production scale.

Related Projects of Mobile Crushing Screening Plant

Our products have been exported to over 90 countries, such as Philippine, Pakistan, Vietnam, Papua New Guinea, Feiji, Tanzania, Ghana, Cameroon, Kenya, South Africa, Nigeria, Somalia, etc.

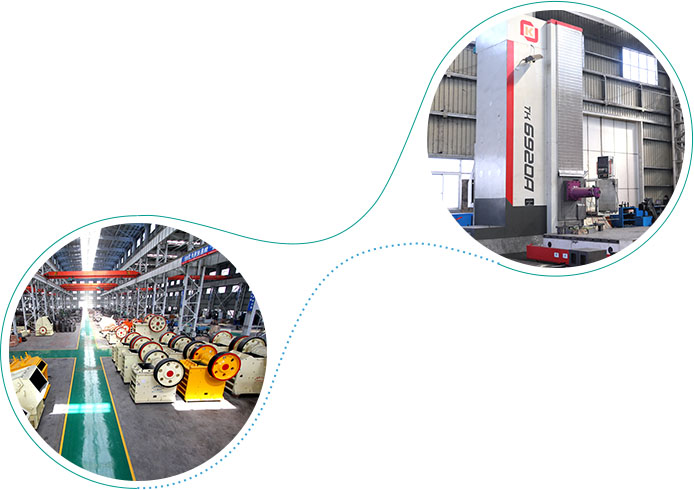

Company Strength

As leading manufacturer and supplier in China, we have three large sized modern workshops, more than 260000 square meters, reliable and trustworthy. We are dedicated to be responsible for every procedure, every product and every customer.

One-stop Solution

We provide full and professional service system, including customized solution, fast delivery, spare parts, product warranty, product installation, etc.

Production Strength

with over 200 kinds of small, medium and large heavy processing equipment, such as vertical lathe,edge planer, large boring machine, bending roll, etc.

![]()