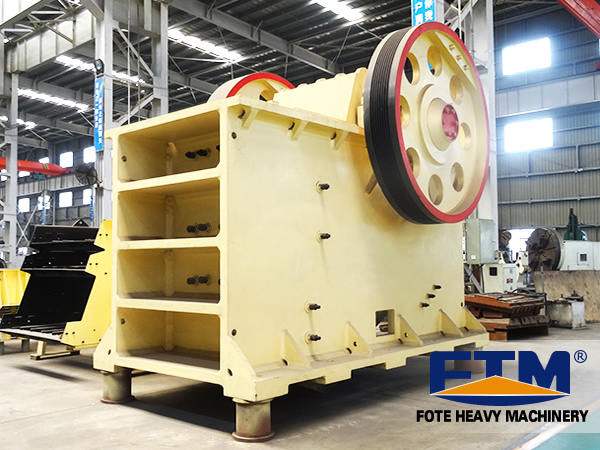

As a common used ore processing equipment in the gravel production line, the jaw crusher is of high crushing ratio. Besides, compared with the other common ore crushing machines, the jaw crusher can be used to crush and process the ore with higher hardness. In other words, the jaw crusher is a kind of necessary processing equipment in the gravel production line.

As for the jaw crusher, a kind of ore processing equipment, Fote Heavy Machinery, as a gravel processing equipment manufacturer, must develop the jaw crusher to the largest extent. Here, Fote will talk about the advance of the jaw crusher in some aspects.

To decrease the machine weight is an important aim in the advance of the jaw crusher. The weight of the rack of the jaw crusher accounts for a large proportion of that of the whole machine. The weight of the casting rack accounts for 50% while that of the welded one accounts for 30%. Casting steel is a high-energy-consumption process. From the perspective of energy conservation, the welded rack should be developed more.

Through repeated research, it is concluded that, for the long-term development, to adopt the welded rack is the optimal choice for the jaw crusher. Besides, the unreasonable structure design of the rack is also a main cause of the increase of the weight of the machine weight. The structure of the rack should be designed on the basis of the force analysis. We should try to decrease the weight of the machine in the structure design, meeting the requirement in the strength and the rigidity of the machine.