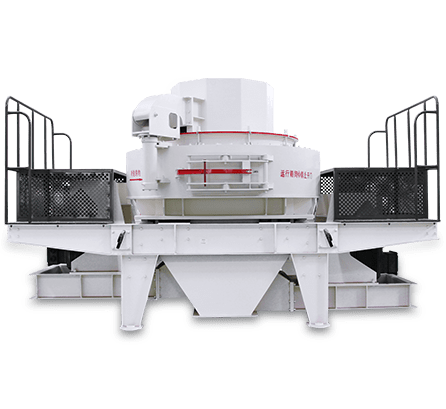

Sand making and shaping

With deep impeller cavity, the stone throughput is increased by 30%. There is a certain shaping effect, reasonable gradation and adjustable fineness modulus.

Durable and easy to maintain

The core components are carefully crafted to be more durable, and the service life is extended by 1.5-3 times. At the same time, the hydraulic cover can be opened, which is more convenient for users to view and repair, and the daily maintenance is simple.

Low Costs

Small footprint, combined throwing head, only need to replace the worn piece, reducing the use cost by 30%.

Environmental friendly and energy-saving

The air flow inside the vortex cavity is self-circulating, working with less dust and low noise, and at the same time, brand-name motors are used, which has sufficient kinetic energy and more energy saving.